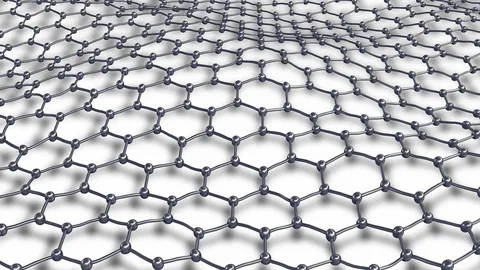

Graphene has revolutionized the field of surface protection through its singular carbon layer which now shapes protective technologies in various industries. The application of graphene coating price leads to superior performance benefits than conventional traditional coating solutions. Premium graphene coatings used for automotive finishes alongside electronic components bring substantial durability and functionality improvements to the products. Manufacturer adoption of graphene coating technology makes products available to consumers that incorporate longer lifespans and better properties. Using premium graphene coatings provides major advantages which makes them a great investment choice for standard applications alongside specific use cases as this study shows.

1.Unmatched Durability and Longevity

Graphene maintains its strength attribute through molecular bonding structures when applied as a protection coat. Quality graphene creates molecular bonds that stand firm against environmental elements that cause regular coatings destruction. Special commercial-grade graphene applications provide three to five additional times of protective service when compared to ordinary market alternatives. Fewer maintenance interventions result from using graphene-coated surfaces since the protective effects operate for substantially longer durations, especially on assets exposed to heavy wear including vehicles, industrial machinery, and outdoor structures. Quality graphene coatings provide extended durability that increases protection through fewer product replacement needs.

2.Superior Water Repellency

When graphene coatings reach high quality standards they establish a surface that forces water molecules to slide away from contact. Water-treated surfaces possess advanced water-shedding function which allows moisture to slide off efficiently with minimal left behind residue. Graphene coatings maintain a hydrophobic state which stops both water marks and mineral buildup and moisture deterioration on untreated surfaces. The water-repellent properties of graphene coatings cut cleaning needs and stop water from entering both boat hulls along with bathroom fixtures, exterior windows and vehicle finishes. After application, the protective barrier becomes visible through a beading effect which demonstrates its effective functionality to users so they feel confident about their purchase.

3.Enhanced Scratch Resistance

The specific carbon atom pattern in graphene creates a protective layer that demonstrates exceptional scratch resistance. Premium graphene coatings protect surfaces by developing an unnoticeable defense that blocks regular surface damage caused by everyday wear. Scientists in laboratories have proven that the application of graphene coatings enables surfaces to resist greater amounts of friction and contact pressure until noticeable damage becomes visible. Such protection proves especially important for mobile devices, kitchen countertops and vehicle exterior materials since they are often touched many times each day. By using graphene coatings which are thinner than human hair the protection stays hidden but effectively protects against surface damage that reduces both appearance and useful life expectancy.

4.Impressive Heat Dissipation

Graphene demonstrates superior thermal conductivity which directly benefits its working capabilities as a protective coat. The application of graphene coating on heated surfaces enables them to dissipate heat before it reaches the point of accumulation. The ability to manage heat serves as an invaluable feature for electronic devices together with engine components and industrial equipment because temperature regulations affect both operational performance and lifespan. Tests verify that surfaces coated with graphene achieve temperature decreases reaching 15% better than untreated surfaces under equivalent conditions. Operational efficiency and energy consumption enhancement occur through the cooling effect which simultaneously acts to protect coated items.

5.Remarkable Chemical Resistance

High-performance graphene coatings develop a strong shield against chemical attacks which would degrade normal surface materials. Most acids and bases as well as solvents and corrosive substances struggle to react with the stable carbon bonds found in graphene. The chemical-resistant nature of graphene coatings makes them suitable protection for laboratory instruments and industrial infrastructure as well as environmental and cleaning chemical-exposed surfaces. The molecular structure functions as a protection layer that allows chemicals to attack it first before they reach the underlying materials. The protective quality protects the service period for valuable assets while ensuring permanent structure integrity for surfaces whose sudden chemical erosion would require replacement.

6.UV Damage Prevention

The superior graphene coating system provides superior UV ray defense which stops sun-induced degradation of surface compositions. The protective property of UV-blocking safeguards the colour brilliance together with material strength in objects like automotive paint and outdoor furniture. The carbon structure works as both an absorber and a dissipation system for dangerous radiation until such time as damaging photo degradation processes that result in colour fade and material disintegration occur. Tests demonstrate that graphene coatings protect surfaces by allowing them to keep their initial look throughout enhanced UV testing protocols. The protection enabled by graphene-protecting coatings offers considerable value to goods requiring a long-lasting appearance because it reduces replacement expenses in sunny areas.

7.Electrical Conductivity Benefits

When included in protective coatings graphene provides beneficial conductive properties. Electrical conductivity in graphene causes uniform static charge distribution which eliminates surface charge buildup that attracts dust and prevents potential electric discharges. The conductive properties of graphene contribute two benefits to electronic equipment protection by acting as an electromagnetic interference shield without detrimental impact on basic protective operations. Because graphene coatings conduct electricity they enable structures to monitor their condition as well as deliver diagnostic functionality. Traditional passive barrier coatings receive advancement through graphene coatings which function both as protective barriers while enabling new capabilities on treated surfaces.

8.Remarkable Flexibility and Adhesion

The top-quality graphene coatings demonstrate enhanced durability because they balance stiff characteristics with pliable ones better than traditional protective films. The multi-faceted nature of coated substances enables their protection against structural changes triggered by bending vibrations and temperature expansion from underlying structures. The molecular structure maintains adaptable bonds that protect most substrates against delamination while resisting movement-related damages. New applications for flexible electronics and vehicles together with architectural elements require graphene coatings because of their flexibility under environmental stress conditions. The strong adhesive bond maintains successful long-term protection since it prevents damaging edge lifting and separation issues.

Conclusion

Quality graphene coating for cars has become an optimal choice for multiple industrial sectors and everyday use because of their unrivalled performance features. Fortify Car Care has superior performance benefits of advanced coatings, proving them better than standard alternatives because they offer both unmatched durability and self-cleaning properties.